Booster Auto Boxes

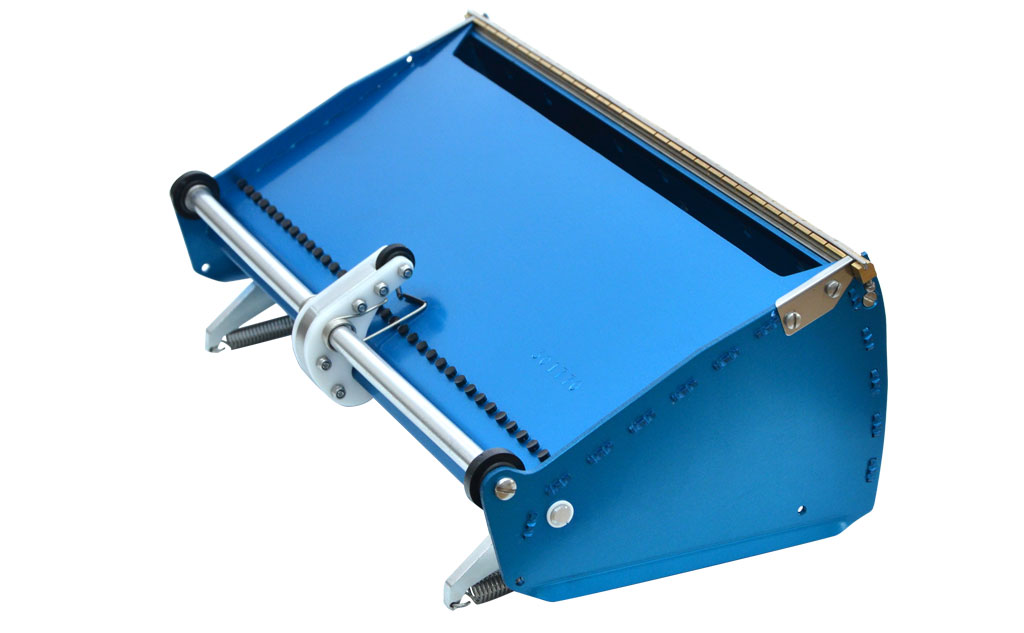

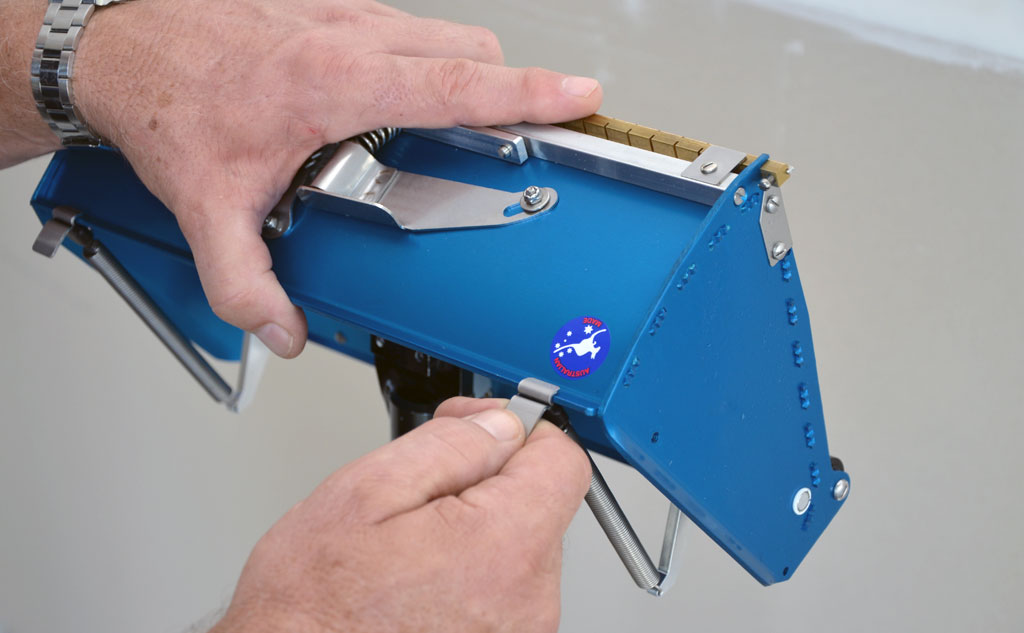

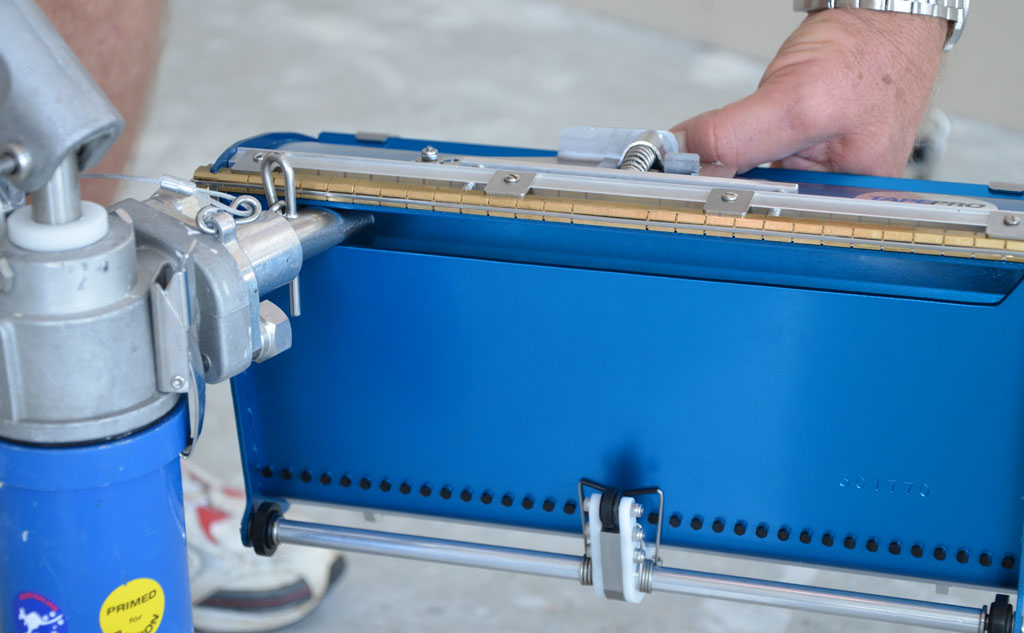

Tapepro Booster Auto Boxes feature a spring loaded pressure plate (lid) that helps force joint compound out of the box. This reduces the effort required and is particularly handy for out of position or difficult to reach areas.

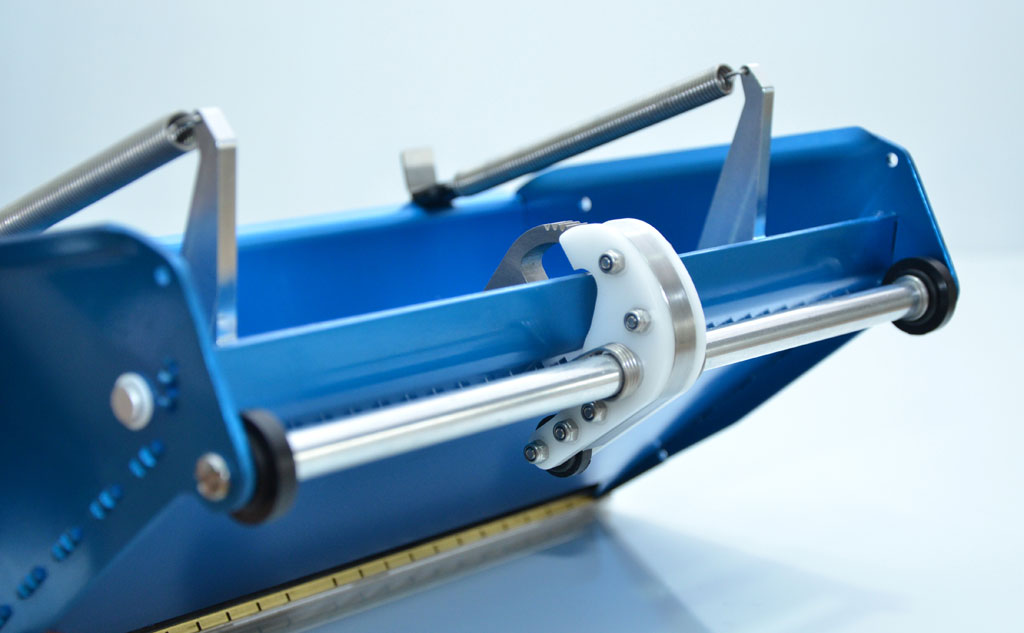

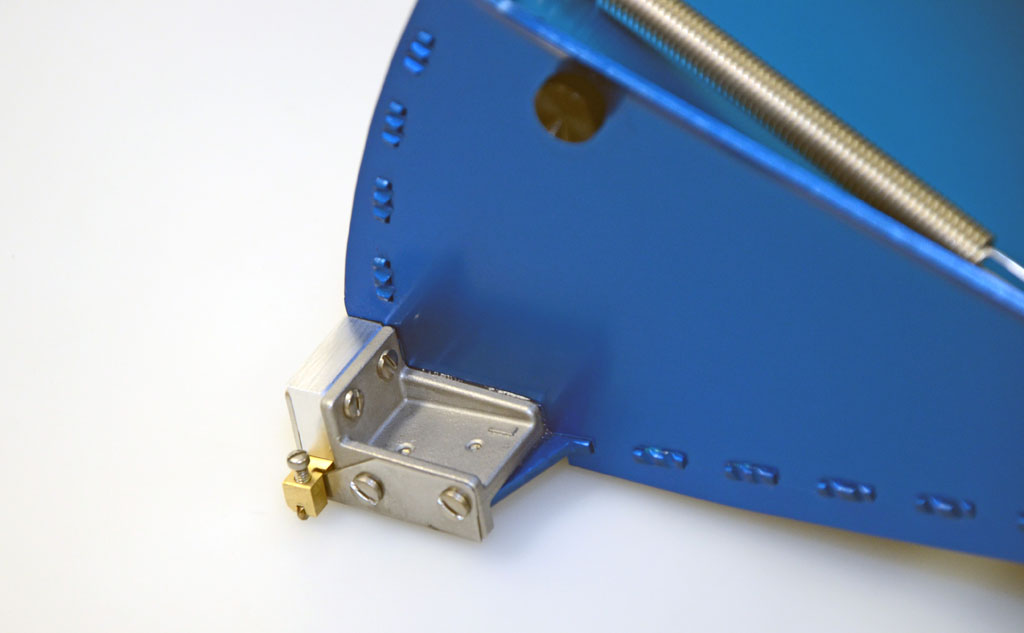

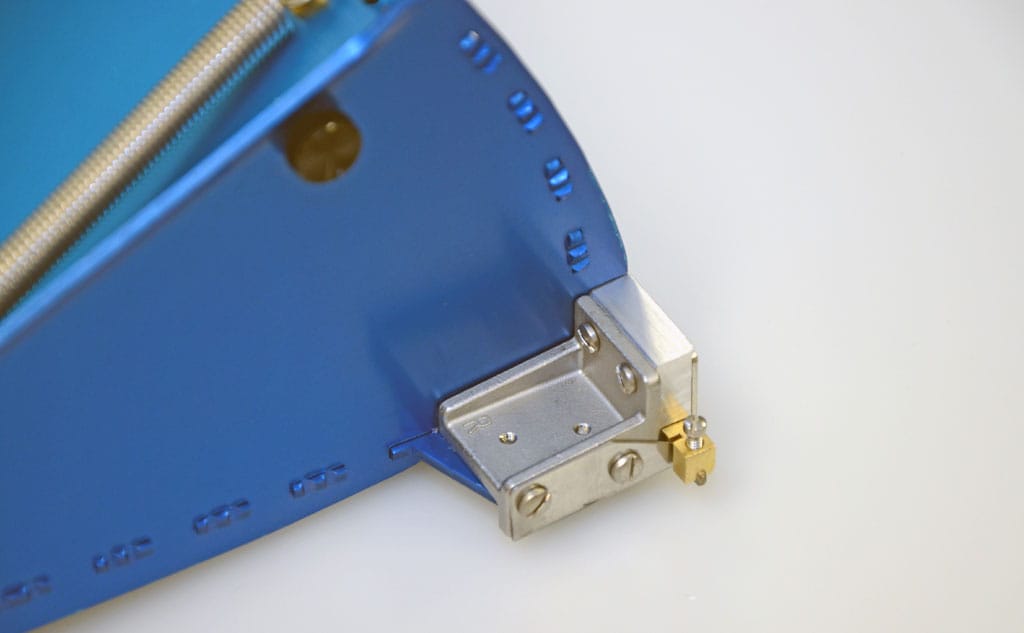

The springs are positioned so that they operate to close the pressure plate. For control, the pressure plate is held in position by a ratchet mechanism which is released when the box is positioned on a flat surface such as a wall or ceiling. The release pawl rotates about the wheel axle, and features a wheel that runs on the underside of the box.

When the box is positioned on the wall, the wheel moves the pawl out of engagement with the arc. This allows the springs to apply pressure to the compound to reduce the force required from the operator. When the box is removed from the wall, the pawl re-engages and prevents the operation of the springs, stopping the flow of joint compound.

- Reverse springs – easier to push

- Durable components

- Easy to operate

- Reduced fatigue

- Can use thicker compound

Now available is a 350mm (14″) version of the Auto Box based on the 300mm (12″) flat box, but featuring a blade holder length of 375mm/14.75”.

We have used innovative plates that mount to the sides of the box to allow the fitting of the longer blade holder and retainer.

This reduces the effort required to push compared to full width 14″ boxes – it feels the same as a 300mm/12″ box.

The wider the box the more the Booster is appreciated allowing easy full coverage.

Perfect for anywhere you want a wider coat: problem framing, raised shoulders, butt joints etc.

Additional information

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Size | 200mm, 250mm, 300mm, 350mm |